Turnkey Box Build Considerations

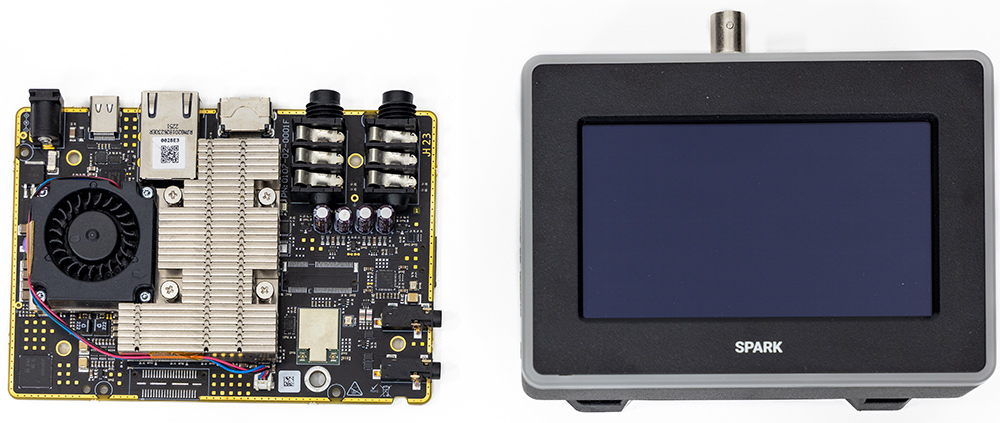

Concepts are coming into fruition. The intricate planning and design of the printed circuit board (PCB) is complete. Yet one critical step remains for its practical use and implementation. That step involves the design, prototyping, assembly, and testing of the entire system inside an enclosure or box. Centralizing all these project elements can increase efficiencies and speed the timeline from concept to market.

Turnkey assembly confines the entire process under one roof, from PCBA manufacture through testing and final shipment. Gain an edge on the competition and avoid the hassle of dealing with multiple suppliers by relying on a turnkey box build and component assembly from a single source.

What is Turnkey Box Build Assembly?

Some OEMs will have an experienced PCBA manufacturer assemble the circuit board, a cable assembly supplier provide the harnesses, a plastics mold injector create the box, and yet another company complete the final assembly. This involves quite a bit of coordination, extra paperwork, and extra shipping arrangements.

A turnkey box build manufacturer with experience in PCB assembly and cable and harness manufacturing centralizes those steps for greater simplicity and a quicker turnaround. While that contract manufacturer specializes in electronics, they can often also recommend a supplier for the enclosure or work with a trusted vendor specified by the customer. With this arrangement, customers can reap additional benefits, such as prototyping, testing, and when required, complete design assistance.

Factors to Consider in a Turnkey Box Build Design

The box or enclosure necessary to house the sensitive circuit boards, cables and wiring involves consideration of several factors, including:

- Size and functionality – Is the product consumer-facing or meant for medical or industrial purposes? Does the final product need to be small enough to be handheld? Or will it be mounted to a piece of equipment or outside a production room in a manufacturing facility?

- Material – Most enclosures are made of molded plastic or metal and are available in any size, dimension, or shape. However, companies serving the aerospace industry for example, might select a different material to reduce weight.

Box type, thickness, and closures all depend on the end-use intended for the finished product. Many customers have a preferred vendor with existing tooling for standard box shapes or repeat orders. However, CO-AX can recommend suppliers for new projects when needed.

- Environment – Material selection and design considerations also depend on the operating environment surrounding the box or enclosure. Environmental factors that influence material selection and design for a turnkey box build include:

- Moisture levels

- Temperature

- Corrosive materials

- Dust exposure

- Shock and vibration

CO-AX is familiar with the guidelines established for intrusion protection (IP). We can help customers determine whether that ratings system should apply to their project design and specifications.

- Design – CO-AX offers extensive experience to assist with design modifications. A customer might need the same internal components or PCBA used in a different configuration. This could alter the box size, shape, or layout. In addition, CO-AX can offer guidance to optimize box build layout for size or shipping considerations, while avoiding interference issues.

- Weight – Consider not just the overall weight of the box, but also weight distribution within the box itself. Weight distribution within the box can impact the recipient’s impression of the product quality. For example, improper distribution or lopsidedness can leave a negative impression. Weight distribution should be taken into consideration during the design phase for a proper layout.

- Connections – The box design needs to incorporate the right number and position of connectors, cables, and harnesses plotted as part of a three-dimensional wiring diagram. There are going to be trade-offs during the design process amidst cost, weight, functionality, and other factors. The goal is to optimize all of the factors for the best value without sacrificing performance. A professionally designed box must take into consideration the factors impacted by the cabling, including:

- Cable routing and location

- Type of cable

- Ease of assembly

- Ease of service

- Cost

- Weight

- Functionality

- Prototyping and scalability – Tooling for the box form itself is expensive and can cost upwards of $20,000 for a single die. Prototyping a box prior to tooling is necessary for a new project or design to keep costs under control. Prototyping also ensures the final product is designed for manufacturability (DFM), repeatable, and scalable.

While the prototyping of turnkey boxes can be time-consuming, it is critical for project success. Once the prototype has been tested and approved, projects can move rapidly and seamlessly to production.

CO-AX supplies prototypes that contain all the elements of the finished assembly, including the PCBA, the cabling, and the box itself.

- Labeling/SKUs – In a borderless global economy, OEMs may need a variety of SKUs and connectors for its box builds. While the internal PCBAs may remain the same, connections and labeling requirements will vary. CO-AX has experience creating multiple SKUs of a similar product for companies with a global customer base.

Questions to Ask a Potential Turnkey Box Assembly Partner

- What Certifications and Standards Do You Hold?

The box or enclosure needs to comply with the regulations of the governing bodies for that particular industry and region, such as UL, CE, or FDA. Look for a company that not only adheres to the highest standards within strictly regulated fields, such as medical devices, but has experience in your industry.

CO-AX’s Quality Management System is ISO 9001 and ISO 13485 certified. We are an FDA registered facility and comply with a long list of other international and regulatory standards.

Learn more about our certifications and expertise within the medical, aerospace, industrial, transportation, consumer goods and smart products industries.

- What are Your Core Competencies and Capabilities?

Are you working with a company known for its experience with electronics design and manufacturing? Does the company offer RoHS, AOI, ICT, FCT, miniaturization, conformal coating, or any other services you may require? Look for a reputable company that does more than just one element of your final electronics assembly to save time, ensure quality, and manage costs.

CO-AX is a leading, full-service electronics contract manufacturer that meets the highest quality standards for custom design and engineering, prototyping, and manufacturing of printed circuit boards, cables and harnesses, integrated electronics systems, and turnkey box build assemblies.

- Do You Offer Engineering and Design Support?

To mitigate risk and get to market faster, you need to work with a company that can help move your design to production quickly. This takes an experienced staff of electronic, mechanical, hardware and software/firmware design engineers with expertise is a wide variety of technologies and industries.

At CO-AX, our design engineers can work with your documentation or co-design with you. Our team will ensure your product meets DFM guidelines, uses available components, and is fully tested to your exacting specifications.

- Can You Handle the Entire Process?

Now that you’ve identified a supplier that has the technology and services you need, you still need to make sure they have the processes in place to move you from design to delivery.

At CO-AX we manage the supply chain, quality, manufacturing, assembly, testing, scaling, and delivery of the finished product. This helps streamline the process for the customer with a single point of contact for the entire project.

CO-AX Technology Inc. is conveniently located in Cleveland, Ohio, USA. As an onshore supplier with global reach, we can help ease delivery and supply chain issues.

For box build assembly services of any size, from one small enough to hold in the palm of your hand to durable units destined for an industrial facility, CO-AX. offers the expertise to supply a turnkey project. Simplify your process without sacrificing quality expectations and work with CO-AX Technology for your next customized turnkey box build. Contact us today.