Printed Circuit Board Assemblies (PCBAs) are the backbone of modern electronics, powering a vast array of devices and systems that undergird the functioning of contemporary society and have become integral to our daily lives. With the rapid proliferation of the Internet of Things (IoT), advanced automotive electronics, 5G telecommunications, renewable energy systems, and innovative medical devices, the demand for high-quality and reliable PCBAs has skyrocketed. In fact, market research reports project the global PCBA market to grow at a robust CAGR of 6-8% over the next few years.

To meet these surging demands, PCBA fabrication has undergone significant transformations, embracing miniaturization techniques, advanced materials, flexible and rigid-flex designs, embedded components, and cutting-edge manufacturing processes. Moreover, the adoption of automation, Industry 4.0 concepts, and smart factory solutions has become imperative to ensure efficient and high-quality production.

This reliance on all things electronic highlights the importance of maintaining stringent quality control (QC) procedures throughout the PCB assembly process. Even the slightest defect or deviation from quality standards can have far-reaching consequences, compromising device performance, safety, and reliability. Robust QC measures enable the continuous advancement of technology while supporting device reliability and dependability.

Although sometimes intertwined or comingled, there is a distinction between quality control and quality assurance (QA).

Quality Control focuses on the production aspect, encompassing processes like:

- Solder Paste Inspection (SPI)

- Automated Optical Inspection (AOI)

- X-ray Inspection

- Functional Circuit Testing (FCT)

- In-Circuit Testing (ICT)

On the other hand, Quality Assurance oversees the manufacturing processes, ensuring they are designed and implemented to produce high-quality products consistently.

What are the key quality control steps in PCBA fabrication?

- Solder Paste Inspection: Before components are placed on the PCBA, SPI is performed to ensure the solder paste is applied correctly. This process checks for issues like insufficient or excessive solder paste, which can lead to defective solder joints and potential component failure.

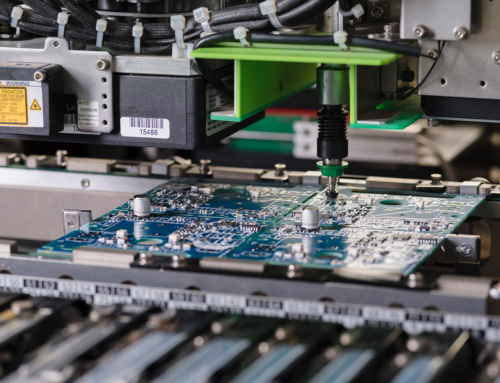

- Automated Optical Inspection: This highly automated process utilizes advanced camera systems and image processing algorithms to inspect the PCBA for defects such as missing components, incorrect component placement, or improper solder joints. AOI can detect a wide range of defects with high accuracy, enabling early identification and correction of issues.

- X-ray Inspection: X-ray inspection is particularly crucial for PCBAs that incorporate ball grid array (BGA) components. These components lack visible leads, making it challenging to visually inspect their connections to the board. X-ray inspection provides a non-destructive method to verify the integrity of these connections, ensuring proper functionality.

- Functional Circuit Testing: Once the PCBA assembly is complete, it undergoes functional circuit testing. Custom-designed test fixtures simulate real-world operating conditions, allowing the PCBA to be thoroughly tested for its intended functionality. This includes verifying power-up sequences, wireless connectivity, and other essential features.

- In-Circuit Testing (ICT): In-circuit testing may be employed as an additional quality control measure for high-volume production runs. ICT involves testing individual circuits and sections within the PCBA using specialized test fixtures and probes. This advanced testing method provides a more comprehensive assessment of the PCBA’s functionality and can identify potential issues that may not be detected by functional testing alone.

What are the benefits of quality control for customers ordering PCBAs?

It is crucial for manufacturers to implement rigorous quality control processes to ensure their PCBAs meet stringent specifications, function as intended, and deliver reliable performance. This not only increases customer satisfaction with the final product but also offers several other key benefits:

- Higher reliability and better performance of PCBAs

- Cost efficiencies by catching and addressing defects early in the manufacturing process

- Reduced waste, rework, and expensive field repairs or replacements

- Compliance with strict regulatory and privacy requirements in industries like medical devices and smart systems

- Fostering strong customer relationships and enhancing market reputation by delivering high-quality products

Manufacturers can ensure that each PCBA meets stringent specifications and functions as intended by implementing rigorous quality control processes. This translates into higher reliability, better performance, and increased customer satisfaction with the final product – enhancing market reputation.

Essential components of quality control in PCBA

At CO-AX Technology, Inc., we understand the critical importance of implementing rigorous quality control processes to ensure our PCBAs meet the highest standards and deliver reliable performance. We employ a comprehensive approach that encompasses several essential components:

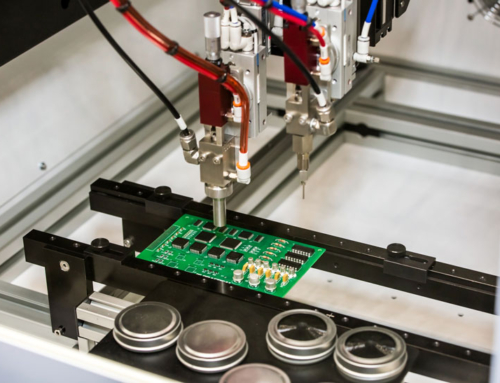

- Automation: Automation is vital in our quality control processes to minimize human error and increase efficiency. We utilize state-of-the-art automated systems, including AOI, SPI, and X-ray inspection, to ensure consistent and accurate production of every PCBA we manufacture.

- State-of-the-Art Technology and Equipment: We have invested in the latest surface mount technology (SMT) lines, through-hole technology (THT) equipment, advanced test fixtures, and specialized software for programming and data analysis. This cutting-edge technology enables us to maintain the highest levels of quality control throughout the manufacturing process.

- Skilled Personnel and Training: Automation doesn’t eliminate the need for skilled personnel. In fact, it highlights the importance of having staff capable of utilizing this advanced equipment to its fullest potential for effective quality control. Our team is comprised of highly trained and experienced professionals who are well-versed in QC/QA processes and procedures. We provide comprehensive training programs and opportunities for continuous learning and skill development, ensuring our personnel stay updated with the latest industry practices.

- Understanding Regulatory Requirements: Depending on the industry and application, PCBAs may be subject to various regulatory requirements and standards. At CO-AX, we have decades of experience supplying components to multiple industries that must adhere to stringent regulatory requirements, operating with a thorough understanding of these regulations. We have designed our quality control processes to meet or exceed the most rigorous standards, ensuring compliance across the markets we serve.

- Experience in Multiple Markets: Our PCBAs are found in applications across diverse markets, including medical, consumer, industrial, automotive, and more. Our expertise helps manufacturers produce the highest quality finished goods that meet and exceed market expectations.

By incorporating these essential components into our quality control processes, CO-AX consistently delivers superior quality PCBAs and finished products/turnkey box builds to our customers.

The CO-AX Quality Difference

Our quality difference begins with documentation and design review.

From the initial customer specifications, our experienced engineers conduct a thorough Design for Manufacturing (DFM) analysis, identifying potential issues and optimizing the design for efficient and repeatable manufacturing.

During the New Product Introduction (NPI) and prototype build stages, we rigorously test and evaluate the design, making necessary adjustments before full-scale production. We build work instructions complete with pictorial guidelines for NPI projects for consistency during assembly.

Throughout the assembly process, we maintain meticulous documentation and revision control. Every step, from component placement to testing, is meticulously recorded and updated, capturing any deviations or tribal knowledge that could impact quality. We follow formal processes for managing engineering change notices (ENC) and deviations, ensuring that all changes are properly documented and approved.

Our commitment to quality extends beyond the assembly line. We have implemented stringent quality control procedures that align with ISO 9001 standards, ensuring consistent and reliable processes across our operations. CO-AX is also certified to ISO 13485 for manufacturing medical devices. Additionally, we maintain compliance with other industry-specific regulations, such as RoHS, REACH, and IPC.

At CO-AX, we believe that quality is not just a casual buzzword; it’s a commitment that permeates every aspect of our operations. By combining state-of-the-art technology, skilled personnel, and a relentless pursuit of excellence, we deliver PCBAs that meet the most demanding performance and reliability requirements.

Whether you’re a manufacturer seeking a reliable PCBA partner for a new project or an existing project with a new contractor, we invite you to explore our website and learn more about our capabilities and processes.

Contact us today to discuss your project requirements and discover how our unwavering commitment to quality can benefit your business.