Panel and Box Build Assembly

Turnkey Box Build Assemblies and Circuit Board Enclosures

For many customers, a printed circuit board assembly, cables, and harnesses also need an enclosure. As a full-service electronics contract manufacturer, CO-AX also designs and produces turnkey box build assemblies to simplify the process and speed your time to market.

When you bring your project to CO-AX, we start with a thorough design evaluation to ensure your product is Designed for Manufacturability (DFM) and cost-effectiveness. Your project then moves to our dedicated supply chain team for a Bill of Materials (BOM) review to address any obsolescence issues. Once complete, your project moves to prototyping, ICT/FCT, and then to full production.

Our expert design engineers can also assist you with box build layout and enclosure material selection. For new project introductions, CO-AX can deliver a prototype in as little as two weeks from receipt of materials.

This integrated approach to design and manufacturing improves the efficiency and quality of your finished product – all from our facility in the USA.

Integrated Design and Contract Manufacturing Services for the Utmost Quality

CO-AX owns and operates a 114,00 SF facility in Cleveland, Ohio, that includes a dedicated box build assembly cell, cable and harness assembly area, five Surface Mount Technology (SMT) lines, through hole assembly (THT), wave and selective soldering, in-circuit and functional testing, automated optical inspection (AOI) conformal coating and more. We also offer fully scalable manufacturing capabilities to help customers better manage market fluctuations.

In-house design engineering, manufacturing, and supply chain teams use industry-leading software, including Altium, SolidWorks, and SiliconExpert, to assess your document package and mitigate risks. Our expertise in DFM, combined with our product development experience in consumer, medical, aerospace, industrial, and smart devices, reduces your time from concept to production and maximizes your profits.

Our Quality Management System is certified to ISO 9001 and ISO 13485, along with a long list of other regulatory and international standards. Every step in our process is meticulously controlled and fully traceable.

We go above and beyond daily to ensure our customers’ complete satisfaction. Our core values of transparency, integrity, and accountability are ingrained in everything we do. At CO-AX, we are committed to providing the highest quality products that meet and exceed your exacting requirements.

Our advantages include:

Tell Us About Your Project

Box Build and Circuit Board Enclosure Capabilities

- Full Cabinet Integration

- Power Distribution Units

- Mechanical and Electrical Assets

- PCBA and Harnesses

- System Integration

- Standard and Custom Builds

Customer Success Stories

This customer asked CO-AX to manufacture a box build assembly onshore. Their current contract manufacturer was overseas and had long lead times on orders exceeding 25,000 pieces. The product was costly and did not function as desired.

CO-AX developed a prototype box build that performed precisely as required. We lowered the customer’s costs by more than 60%, reduced the lead times, and provided flexible order quantities – vastly improving the customer’s profit margins and time to market.

What Are the Processes of Box Build Assembly?

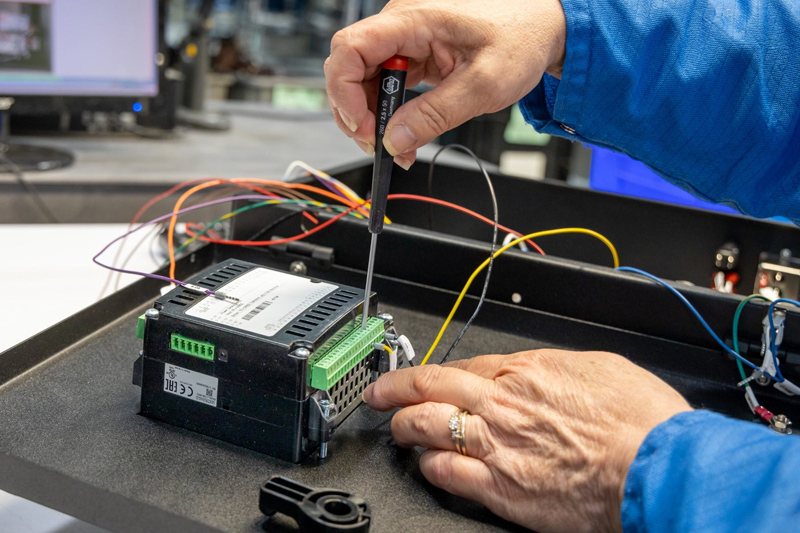

Many times the box build begins with an enclosure – the outer container that holds all the electronic circuitry that makes a product function to specifications. Boxes can be plastic or metal, adorned with a company logo or nondescript, and in some cases, as with a modem, for example – the box is the finished product itself. The enclosure must be sized appropriately to house the required printed circuit board assemblies, cables, harnesses, and other components. It must also be constructed to accommodate any harsh environments or other use cases requiring special design considerations.

The components that go into the box build itself are specified, laid out and typically include a set of work instructions for assembly. Qualified assemblers then utilize these work instructions to build the components inside the box, creating the necessary connections for the circuitry to operate as intended. It is critical that these assemblers follow ISO-certified quality management processes and procedures to ensure the final box meets all specifications. Box builds for the medical industry require manufacturers of Class I and II medical devices also have an ISO 13485 certified quality management system.

Testing is recommended for the PCBAs individually, and then a functional test on the final assembled unit is completed. Designing and developing this test can be accomplished by a contract manufacturer, collaboratively with the OEM’s engineering and design team, or solely by the OEM.

Finally, the box is packaged into a specified container for shipping to the OEM or the end user. When going directly to the user, the packaging may also include documentation, such as user manuals, installation instructions, power adaptors and other materials to facilitate the use of the product.