In a recent LifeSciencesNY member spotlight podcast hosted by Winthrop Thurlow, Chris Cassan, Director of Sales & Marketing at CO-AX Technology, Inc., shared insights on the company’s role in medical device innovation. Based in Cleveland, Ohio, CO-AX has strong ties with the New York Life Sciences community, contributing to the institutions and organizations along the healthcare corridor spanning from the Midwest to the East Coast.

Cassan highlighted CO-AX’s commitment to early collaboration with clients, offering design for manufacturability (DFM) insights during the prototype phase to streamline production and regulatory approvals. He discussed the trend towards remote monitoring and home healthcare solutions, driven by rising costs and patient-centric care models. Cassan emphasized CO-AX’s approach as a strategic partner deeply invested in clients’ success, combining production capabilities with expertise in navigating medical device development. The interview underscored the importance of cross-regional partnerships and early-stage collaboration in advancing healthcare innovation.

CO-AX Technology’s Chris Cassan Shares Insights on the Intersection of PCBAs and Medical Device Innovation in LifeSciencesNY Podcast

Recently, Chris Cassan, Director of Sales & Marketing at CO-AX Technology, Inc., had the opportunity to sit down for an interview with Winthrop Thurlow, host of the Member/Partner Spotlight series of podcasts recorded by LifeSciencesNY. CO-AX, a Cleveland-based contract manufacturing company, specializes in designing and fabricating printed circuit board assemblies (PCBAs), many for medical devices. This specialty was one focus of the interview as Thurlow questioned Cassan about his observations and predictions for the future of medical devices and healthcare technology.

Thurlow is Executive Director at LifeSciencesNY, a non-profit association that promotes the biotech/biomedical industry across New York state. Thurlow’s entire career has been devoted to promoting New York companies and the state’s economy, including serving eight years as an Assistant Attorney General and nine years as a general counsel to NY State Medical University.

Cassan serves on the board of LifeSciencesNY and shared a few reasons why a company in the Midwest finds value in partnering with organizations on the East Coast. First, Cassan mentioned the importance of the innovation corridor stretching from Cleveland through western Pennsylvania to New York and the rich tapestry of universities, research institutions and technology companies along the corridor, all fuel advances in the life sciences sector.

Secondly, Cassan discussed a trend among companies to reshore vital fabrication services that formerly were assigned to offshore vendors. Reshoring has ramped up for a few reasons, including hefty tariffs on imports (up to 30%), an effort to solve logistical nightmares experienced during the COVID-19 pandemic, and growing geopolitical uncertainties in Asia.

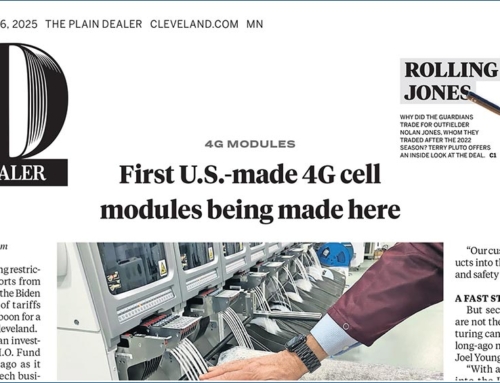

Fully automated production lines speed the assembly process and cut the cost of PCBs for medical devices and other electronics assemblies, making it more practical to reshore PCBA and turnkey box builds. Proximity to the manufacturer allows for greater flexibility, enabling companies to pivot quickly in response to market demands or regulatory changes. Customers are always welcome to pay personal visits to the CO-AX facilities.

Forestalling Potential FDA Issues Upfront

A key takeaway from the interview was CO-AX’s commitment to early-stage involvement with clients. Cassan stressed the importance of close engagement and open communication when products are still in the prototype phase. This early collaboration allows CO-AX to offer critical insights on design for manufacturability (DFM). This can reduce costs, improve quality, and streamline scaleup for mass production. Importantly, Cassan noted that making these adjustments before FDA approval can save considerable time and resources, as post-approval changes can be cumbersome and expensive.

The discussion also touched on the ideal customer profile for CO-AX. The company works with startups and established firms, but typically seeks partnerships with businesses projecting annual spending of $750,000 or more. Most of the current clientele surpasses the million-dollar mark annually.

Finally, Cassan shared his perspective on the growing trend of remote monitoring, wearables, and implantable devices. He foresees a continued shift towards home healthcare solutions driven by rising hospital costs and the need for more patient-centric care models. This transition, he believes, will heavily rely on electronics and cloud-based technologies. However, with this shift comes new challenges, particularly around data security and software integrity—areas where the FDA is increasingly focusing its scrutiny.

The shared mission among innovators in the field of life sciences, said Cassan, often transcends business relationships, fostering long-term partnerships built on mutual understanding and respect.

The dialogue also underscored the significance of networking events and personal connections in the life sciences ecosystem. Cassan likened the initial stages of business relationships to “dating,” where parties get to know each other’s values, aspirations, and working styles.

The Contract Manufacturing Partnership

The podcast emphasizes the commitment at CO-AX to be more than just a contract manufacturer. Under the leadership of individuals like Cassan, who have decades of experience in the electronics distribution sector, the company is a strategic partner deeply invested in its clients’ success. By offering production capabilities and expertise in navigating the complex terrain of medical device development—from prototype to market—CO-AX exemplifies the evolving role of modern contract manufacturers.

The conversation with Cassan served as a reminder of the interconnectedness of the US life sciences landscape. Despite being based in different regions, companies like CO-AX and organizations like LifeSciencesNY find immense value in collaboration, driven by shared goals of advancing healthcare and improving patient outcomes.

As medical technologies evolve, becoming smaller, smarter, and more user-friendly, the insights shared by industry veterans on podcasts, such as those from the Spotlight series, become invaluable. Experts like Cassan offer a roadmap for navigating the challenges of bringing innovative products to market cost-effectively, efficiently, and reliably. It emphasizes the importance of strategic partnerships with contract manufacturers like CO-AX, the value of early-stage collaboration, and a deep understanding of the technical and regulatory landscapes.

For information on CO-AX’s contract manufacturing services, Contact Us or call (440) 914-9200.