In today’s global economy, the impact of the supply chain crisis has every business and consumer in industrialized nations striving to make and find the products that have become an integral part of our interconnected world.

A supply chain includes every person, organization, and activity involved in the process of sourcing raw materials, forming those raw materials into a product, and delivering that product to the end-user. With so many moving pieces, supply chains are inherently unstable.

Supply chain crises are not new. In fact, in 1973, Johnny Carson, host of The Tonight Show, made a joke about an impending toilet paper shortage. And his 20 million viewers listened – rushing to the stores to stock up, gutting inventory, and causing a national shortage. (Sound familiar?) In 1991, sports apparel leader Nike took no accountability for poor working conditions at its factories in Indonesia.

The result was a global boycott that lasted for years, significantly reducing demand for its products. In 2005, Hurricane Katrina blasted the Gulf of Mexico, blocking the passage of container ships to critical ports in Louisiana and Texas. And in 2012, an explosion at the Evonik plant in Germany caused a six-month delay in the production of nylon 12. This created a shortage for automakers who relied on this material to manufacture brake lines, fuel lines, and seat covers.

The current supply chain shortages are global, and they aren’t limited to a single brand or country. This worldwide crisis is affecting everything from cream cheese to cars. This blog will discuss how shortages in the semiconductor industry have become a major constraint and what manufacturers can do to navigate these challenging times better.

Technology Supply Chain Issues We’re Facing in 2022

In this age of the Internet of Things (IoT), nearly every home is loaded with smart products – from thermostats to light bulbs to artificial intelligence devices that help us manage every tasks. Manufacturing has also adopted the Industrial Internet of Things (IoT) with sensors that send signals to remote monitoring stations to machine-to-machine communications systems that improve the efficiency and safety of a processing line.

At the heart of it all is technology – microchips, semiconductors, printed circuit boards, and electronic control systems that drive our connected world.

When COVID first hit and people stayed home, demand for technology initially dipped. Incomes were down, automakers were not selling cars, and consumers were not investing in luxury devices. This had a Bullwhip Effect on manufacturing, which was already struggling with labor shortages.

As the recovery started to take place, however, demand soared. Work-from-home became almost universally adopted, so people needed more computers, modems, smartphones, cameras, cables, printers, and other electronic devices to keep commerce running. Shoppers began ordering online, so retailers needed more hardware to fill orders. Remote education meant that parents and teachers needed the equipment necessary for home school. Telehealth added demand from the medical sector. This rapid and colossal increase in demand put a huge strain on the semiconductor industry.

To further exacerbate the problem, accidents and natural disasters have plagued microchip foundries worldwide. Taiwan, China, and South Korea own more than 85% of the global semiconductor market, with Taiwan Semiconductor Manufacturing Company (TSMC) holding over a 50% share. In 2021, Taiwan faced its worst drought in more than 50 years, forcing the country to reduce its water supply to TSMC, Micron, and other manufacturers in the region. TSMC alone uses more than 40 million gallons of water per day in its chip-making processes. Despite its significant recycling efforts, pumping and trucking water in from other locations, the impact was substantial. Add a succession of fires at microchip plants in Taiwan, Japan, and Germany, and some analysts are predicting the technology industry will continue to see shortages through 2023.

Problems with global logistics are also contributing. While the number changes day to day, it is estimated that nearly 20% of the world’s cargo ships are awaiting unloading at their destination terminals. The recent resurgence of COVID in Shanghai has resulted in additional lockdowns and closed ports, with 30% of those cargo ships backlogged in that region alone.

Tips for Managing the Supply Chain for Your Business

The past two years have been exceptionally challenging for the semiconductor industry. However, manufacturers of equipment utilizing microchip technology can take steps to work through this ongoing crisis and be better positioned for new opportunities when supply chains return to normal.

Decide Which Options are Best for Your Business

With lead times reaching 52 weeks or more for even the most commoditized components like capacitors and resistors, strategic and tactical planning for your production is critical. Your options include:

- Forecast 1-2 years outFind suppliers and contract manufacturers with the industry knowledge, supply chain resources, and financial wherewithal to help carry the planning and inventory load. Expect buying agreements and deposits to be part of the deal, as no one wants to be left with inventory once orders are filled.

- Design for AvailabilityThe idea of changing a product design due to supply constraints is a painful pill to swallow. The process can take a long time, but extraordinary times call for extraordinary measures. Work with partners that can help you identify parts with the same form, fit, and function to get your products to market.

- Get Strategic with Your PricingWhen demand is high, and supply is low, prices go up. This is an unwelcome but accepted rule. Your pricing position leaves a long-term brand impression on your customers. Just as some providers were gouging in the early days of the pandemic, reacting to the crisis in the form of price increases without adding value may send your customers running to your competition. Yes, you are paying more today than before the pandemic, but you must utilize thoughtful planning that helps you manage your margins while retaining your customers and market position.

- Delay New Product Introductions (NPI)Being first to market is not as important as having products to sell right now. You can still do the design work and even begin your sourcing efforts, but consider whether this new product – or a consistent revenue stream – is most important to your survival.

- Reduce Features, For NowSome automotive manufacturers are de-featuring their cars to reduce the need for chips. For example, a consumer can purchase a new car now without heated seats with the promise that they can return to have the feature added to their vehicle once the chips are available. With some creative thinking, you may be able to apply this same methodology to your products.

- Work with Well Qualified PartnersIn this unprecedented environment, it’s more important than ever to find a partner that is as agile, if not more so, than you. Look for companies where you are more than just a number. A contract manufacturer with an established network of franchised distributors and brokers will be more capable of sourcing branded and alternative components from around the world.

What Does the Future Hold?

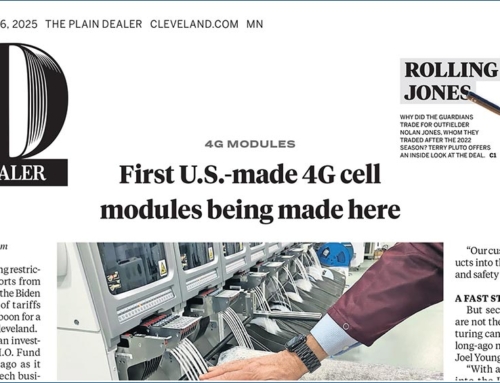

Chip fabricators are adding production capacity to their existing facilities at a rapid rate. Intel, Samsung, TSMC, and Texas Instruments are collectively investing nearly $100 billion in new chip manufacturing facilities in the United States. This will help meet growing demand, create new jobs, and return some balance of geographic availability for the world supply. These facilities will take years to come online, though. Shortages for some industries are expected to persist into 2023, according to this article published in Electronic Design.

Some leading-edge companies are decoupling their software and hardware, as well. Leveraging cloud-based solutions that reduce the demand for chips is a movement that is expected to gain traction as supply chains continue to lag.

One of the most important takeaways of this crisis is to evaluate our ability to be resilient in challenging times. The uncertainty has organizations re-thinking their design, supply, pricing, NPI, go-to-market, globalization, and trade strategies. We can and should expect the way we do things to change forever and bring on a new era for industry worldwide.

CO-AX Technology – Your Partner for Growth

CO-AX Technology, Inc. was founded in 1993 as a PCBA and cable assembly contract manufacturer. Today, we are a total solutions contract manufacturer with expertise in design engineering and state-of-the-art manufacturing of PCBAs, cables and harnesses, and turnkey box builds.

Our mission is to exceed your expectations through continuous improvement in quality, cost, technology, and services. Our culture of transparency, accountability, respect, and teamwork is at the core of all we do. Our goal is to earn your trust and become your preferred electronics assembly contract manufacturer

Proactive Supply Chain Management

CO-AX works closely with leading distributors and brokers around the globe to secure the materials required to provide our customers with reliable, turnkey electronics assemblies. We manage the supply chain for you by utilizing Silcon Expert for lifecyle management, so you can focus on growing your business.

From receipt of raw materials to shipping finished orders, every step in our process is meticulously controlled and recorded, including labor and product yield. We utilize the industry’s leading software to manage the product lifecycle and ensure the highest quality assemblies. Our proactive approach to risk mitigation includes bill of material (BOM) assessment, counterfeit detection, regulatory compliance monitoring, and obsolescence forecasting.

You also get a dedicated Customer Focus Team watching out for your best interests. This includes experts in Purchasing, Documentation Control, and Program Management. Our buyers work alongside you to better understand every facet of your demand to serve your needs. Continual and open communication ensures you stay well informed of your supply chain options so you can plan accordingly.

Are you evaluating electronics assembly providers? Contact CO-AX to learn more about our contract manufacturing transfer process.