Fresh winds are blowing away the dark storm clouds of supply chain snarls that plagued the tech industry, which was dislodged during the global COVID pandemic. As we head into 2024, the pandemic era experiences left behind valuable lessons and sparked new practices implemented at CO-AX Technology to help our customers.

Factors Easing the Electronics Supply Chain Slowdowns

As we look towards 2024, we have witnessed significant improvements in the PCB supply chain. This is due to a few identifiable factors:

- Inventory adjustments: Companies employed various strategies to cope with part shortages during the pandemic, including storing extra inventory, placing double or even triple orders, and buying through non-traditional channels. Now, these companies are working through private inventory stockpiles and returning to pre-pandemic purchasing patterns and order quantities.

- Recovered Production Capacity: As factories around the globe recover from slowdowns caused by plant shutdowns and labor shortages, production is returning to pre-pandemic levels. This has resulted in shorter delivery times, although not what was considered “normal” pre-pandemic. Delivery estimates are one-third longer than in 2019, for example, instead of twice or four times as long, which was the case in 2021 and 2022, when delivery times could stretch to a year or more. Today, many parts are in stock and readily available.

New Practices Streamline Customer Communication

Contrary to the saying “no news is good news,” CO-AX took its culture of open communication and expanded it into over-communication. No company was immune from the supply chain challenges, and we learned that our culture of complete transparency with customers solidified trust during the crisis. We instituted new practices that proved worth keeping in place as we emerge into a new manufacturing era.

We routinely update clients about order progress, potential obsolescence, and price changes. Now, we are diving into much greater detail about board assemblies than ever before. New PCB supply chain practices include notifications about:

- Parts that require sourcing from a broker

- Any deviation from standards on shipping methods or freight costs

- Any shipping delays due to parts shortages

- Increases in the BOM component pricing

PCB Supply Chain Practices We Instituted

- Adaptive Design Flexibility: We worked closely with customers, displaying remarkable agility to devise solutions to parts unavailability. We offer Design for Availability expertise, examining potential obsolescence and pricing issues, and providing design engineering support to keep projects moving.

- Vendor Diversification Capability: Recognizing the cost implications within a bill of materials, especially when 80% of the cost is concentrated in 20% of the parts, we proactively expanded our list of approved vendors. This action helped mitigate the impact of both part shortages and price increases. These expanded resources bolster our resilience to supply chain disruptions, provide more reliable production timelines, and help customers manage their profitability.

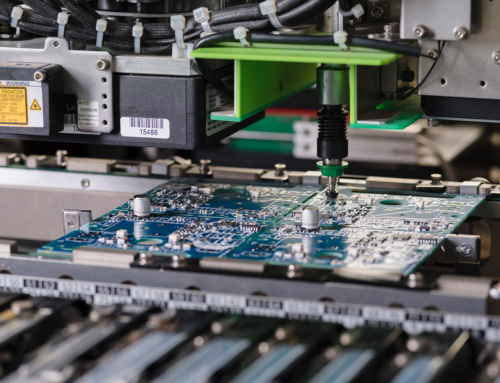

- Enhanced Order Monitoring: Before the pandemic era, routine order tracking sufficed. However, with the pandemic changes, we instituted weekly customer reviews to meticulously monitor each parts order to forestall and plan around potential delays or shortages well in advance. This provides a more seamless production experience for our customers.

- Vigilant Freight Cost Surveillance: Historically, freight costs were a minor concern for our purchasing department because costs did not vary a great deal. The pandemic and its aftermath changed that. These recent challenges underscore the significance of freight costs and shipping methods, prompting us to closely monitor freight fluctuations. This awareness ensures that we account for every variable, further fortifying our resilience within the supply chain.

- Leveraging Logistical Tools: Amid supply chain chaos, tools like SiliconExpert became indispensable. With the capability to track part obsolescence, it was a beacon of information that guided us through the pandemic’s murky waters. Even as the direct effects of the pandemic wane, these tools will retain their value, ensuring that CO-AX stays ahead of lifecycle changes on components.

A Brighter Road Ahead for Electronics Manufacturing

The shadows of the past few years still loom large, but they also cast a path toward a brighter future for supply chain dynamics.

- Tariffs and Domestic Collaborations: Tariffs have reshaped the global trade landscape. While they may increase the cost of certain parts, they also present an unexpected benefit – companies are increasingly opting for domestic suppliers over overseas counterparts. This shift ensures a more resilient supply chain and fosters national economic growth.

- Investment in Domestic Production: The lessons from the pandemic were clear—the peril related to over-reliance on international sources, especially for critical components. As a result, there is a significant movement to return to domestic manufacturing. New construction is underway, for example, on two new chip factories in Ohio and Arizona. Rooted in national security interests, these ventures promise to drastically ease component shortages when they commence production in the coming years.

- Anticipation of New Product Introductions: The past few years have seen design engineers in survival mode, focusing primarily on keeping existing product lines functional. The bulk of technical resources were channeled towards adjusting existing products. However, as the supply chain relaxes its tight grip, we can expect a surge of creativity and innovation. New product introductions are on the horizon, particularly as new AI technologies are rolling out. There is palpable excitement for what the next year will bring. The post-crisis phase often witnesses a boom in innovation, and as the dust settles, we eagerly await the fresh wave of products birthed from past challenges and next generation products.

Navigating through the challenges of the pandemic, CO-AX focused on a collaborative approach, partnering with customers to navigate pandemic and supply chain challenges. The resulting journey illustrates our commitment to problem-solving. The tactics we adopted and the new policies enacted focus on finding solutions in the face of adversity and will pay long-term dividends for CO-AX and its customers.

One final lesson was engraved in our psyches during this time – that there is no “normal” business atmosphere. Companies that succeed no matter the climate will be agile, committed to excellence, and transparent with their stakeholders. As we look ahead, we carry those core values and new practices for the coming years.

CO-AX Technology – Forging New Partnerships for Growth

Post-crisis landscapes demand partners who understand the past and are equipped to innovate for the future. With its rich history and expansive expertise in design engineering and advanced manufacturing, CO-AX Technology strives to earn trust with a focus on reliability.

We offer comprehensive solutions for printed circuit board assembly, cable and harness fabrication, and turnkey box builds. Our proactive approach to supply chain management, combined with a commitment to transparency, accountability, and teamwork, ensures that your company and your business remain ahead of the competition.

Our dedicated Customer Focus Teams leverage cutting-edge industry software and techniques, prioritizing your needs and ensuring open communication so you are always informed and empowered.

As we enter a new era of opportunities, you can rely on CO-AX as a trusted partner, whichever way the winds blow. Contact us for help with your next project.