Anyone involved in the design and manufacture of electronic components and circuit boards destined for use in harsh environments is likely familiar with printed circuit board assembly (PCBA) potting and conformal coating processes. Imagine aircraft that travel at supersonic speed, industrial machinery for mining operations, deep sea oil drilling equipment, or Class III medical devices. It becomes apparent that the printed circuit boards within these applications need protection from environmental hazards like moisture, chemicals, vibration, and temperature extremes.

Two common solutions for this are PCB potting and conformal coating. Learn what each process entails and the differences between the two to make an informed decision.

What is PCB potting?

Potting is the process of encapsulating a printed circuit board and its components in a dense, rigid compound. Depending on the required protection, the potting compound can surround a single component or the entire board. When the whole board is potted, it is typically done by placing the PCB in a mold or casing and then filling the void around it with a liquid potting compound. Once the potting compound cures and hardens, it forms a solid barrier that protects the internal components.

When do you need PCB potting?

PCB potting protects electronic components from the hazards of extreme temperatures, wet conditions, corrosive environments, mechanical stress, high altitudes, and other environmental pollutants. Its benefits include:

- Moisture and chemical resistance: The PCB encapsulation seals out moisture, corrosive gases, and other harsh chemicals that could damage components.

- Vibration damping: The potting material absorbs shocks and vibrations that could otherwise cause hairline cracks and other damage to the PCBA.

- Temperature insulation: Many potting compounds have low thermal conductivity, protecting PCBs from extreme hot or cold temperatures.

- Physical protection: PCB encapsulation shields components from physical impacts that could bend leads or snap off surface-mount devices.

What are the types of PCB potting materials?

Potting compounds come in different formulations depending on application requirements. Commonly used options include epoxy, polyurethane, and silicone-based compounds that can withstand temperatures from -65°C to over 200°C. Some specialty compounds provide additional properties like low smoke emissions or UL certification for fire resistance.

- Epoxy potting: Epoxy potting compounds are rigid, durable, and offer excellent adhesion, chemical/moisture resistance, and high thermal conductivity. However, they have limited flexibility and can be brittle.

- Polyurethane potting: Polyurethane potting compounds are flexible, impact-resistant, tear-resistant, and adhere well to metals/plastics. They have moderate chemical/moisture resistance but lower thermal conductivity than epoxy.

- Silicone potting: Silicone potting compounds are highly flexible, vibration-resistant, have excellent thermal conductivity, good electrical insulation, and resist moisture, chemicals and extreme temperatures. However, they may require surface preparation for proper adhesion.

The choice of potting material depends on the application’s unique needs and can vary by customer preferences. CO-AX consults with customers and can supply guidance based on decades of experience and a singular focus on designing and fabricating printed circuit board assemblies for multiple industries.

Differences between conformal coating and PCB potting

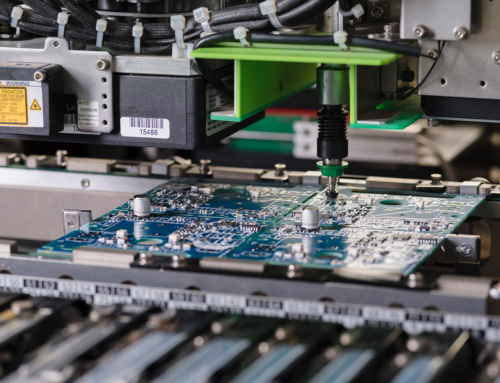

PCB potting and conformal coating are part of the turnkey contract manufacturing services offered by CO-AX Technology to existing customers that require this step as part of a larger PCBA or box build project.

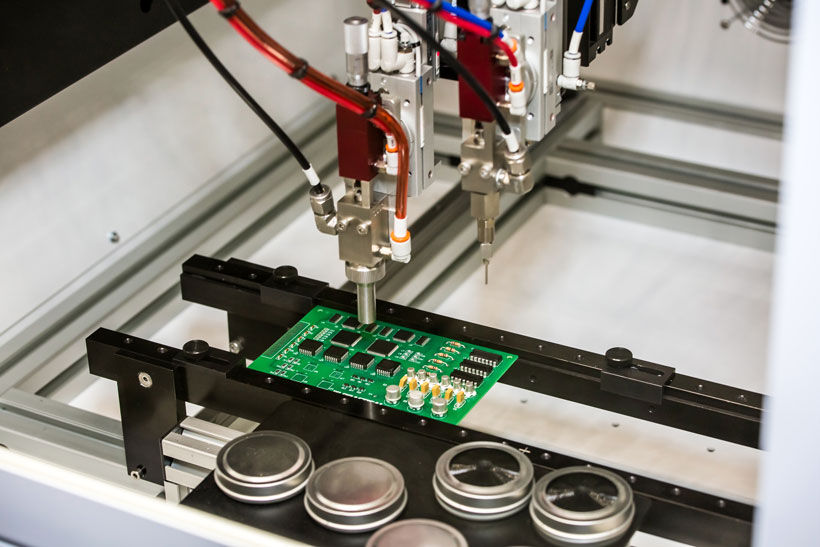

Our potting services use a systematic approach that yields consistent results by using dispensers. The dispensers help mix and blend the right amount of material and applies it in precise quantities to each component or board for the specified level of PCB protection.

CO-AX provides complete traceability and accountability for the electronic assemblies we design and manufacture. Our PCB potting and conformal coating service and expertise ensures your boards receive the proper protection to withstand their intended operating environments while enhancing their functionality and extending their lifespan.

Don’t leave the reliability of your PCBs to chance – partner with CO-AX. Our state-of-the-art facilities, automated processes, and stringent quality controls guarantee consistent, defect-free electronics assemblies. Contact us today for a quotation on your next project.