Electronics Prototype Engineering and Manufacturing

Highly Optimized PCBA Prototyping Services

With CO-AX, your PCBA design moves from proof of concept to prototype in just one to two weeks from receipt of materials.

We accomplish this through our investment in a dedicated Surface Mount Technology (SMT) line and work cell, which are used solely for onboarding new projects and prototyping of new PCB assemblies. We use the same SMT equipment in our production lines so that you can move from prototype to full-scale production seamlessly.

Integrated Engineering, Prototyping, and Manufacturing Process

It all starts with your document package. Once received, our design engineers and supply chain experts assess and evaluate your design and Bill of Materials (BOM) to ensure Design for Manufacturability (DFM), parts availability, and scalability to full production.

Your product then moves to the NPI line for prototyping. Prototyping ensures your product can be assembled as instructed without defects or inefficiencies. If any exceptions are identified, we work closely with you to resolve those issues. We can then repeat the prototyping process to get your product to its final design. Our engineering teams can update your documentation, as well, so you know your design, assembly instructions, and BOM remain current.

At CO-AX, we are committed to innovation and helping our customers get their products to market rapidly. Our goal is to take the stress out of the NPI process, creating products that meet your requirements and customer needs while maintaining the highest quality, reliability, and cost-effectiveness.

Let’s Talk About Your Next Project

Rapid PCBA Prototyping for Faster Time to Market

Customer Success Stories

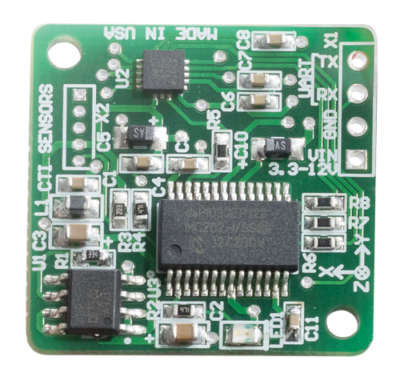

When the principal design engineer at one customer resigned, they soon learned that the engineer had not kept up with assembly revisions. Further investigation revealed that the schematic and drawings were up to seven revisions out of date.

Our engineering team took the original product, drawings, and schematic and successfully developed a smaller, more cost-effective prototype. Our prototype had improved functionality, as well. It is in full production to this day.

What is a PCBA (Printed Circuit Board Assembly) Prototype?

A printed circuit board assembly prototype, also known as a PCBA or PCB prototype, is an initial version or sample of a printed circuit board design created for testing and validation purposes before moving into production. A PCB is a crucial component in electronic devices, providing a platform that houses the components that enable those devices to operate as planned, including resistors, capacitors, integrated circuits, and connectors.

During the development of a new electronic product, it is common to create one or more PCB prototypes to ensure the design functions correctly and meets the desired specifications. A prototype allows engineers and designers to test the circuitry, validate the layout, and identify and correct any potential issues before moving on to large-scale production.

It is during the prototype phase that engineers can implement design for manufacturing (DFM) principles. Certain components may have limited availability, a potential end-of-life notice (EOL), long lead times, or prohibitive costs. The prototype phase addresses scalability and product lifecycle issues early, examining possible alternatives for design and component substitution.

With a qualified electronics contract manufacturing partner, your PCB prototype is manufactured using the same processes and materials as the final production boards – and with a quick turnaround, fast-tracking the testing and validation needed to get to market faster.